Valorization of Agri-Food Wastes

Wastes resulting from the production of food and drinks has always been considered not valuable and their management is problematic and expensive for manufacturing companies. However, these wastes very often still retain a high content of bioactive substances with high added value. For this reason, in recent years, scientific interest is growing in processes that efficiently and inexpensively extract these substances. In this way, following a biorefinery concept, a waste can be valorized becoming a promising resource, subsequently limiting the environmental impacts connected with its direct disposal. In this context, the research team, coordinated by Prof. Patrizia Perego, studies innovative and alternative techniques for the extraction of active compounds from agro-industrial residues through high pressure and temperature, ultrasound, microwave technologies, sub and supercritical fluids. The combination of these methods allow a full and fast extraction without degradation of the thermally unstable compounds. Operative parameters effects are studied for each extraction method and matrix, including temperature, time, solvent, drying of the extracted matrix effect, etc.. Olive pomace, spent coffee grounds, tomato wastes, apple skins are a few examples of the treated and valorized matrices.

The CN-Agritech Project

Within this research field, CN-Agritech is an ongoing project which fits into the context of the European Green Deal, part of 2030 Sustainable Development Agenda, with the aim of stimulating a circular economy and reducing waste in the agri-food sector. In particular, the Food Engineering Laboratory is directly involved within the Spoke 6 “Management models to promote sustainability and resilience of agricultural systems”, and, more in detail, it is co-task leader for the task 6.2.1 “Selection and adaptation of the most promising new technologies for combining biowaste upcycling into new farm models” that aims to develop unconventional technologies on a pilot scale. This research is focused on a specific food waste, typical of the Ligurian territory: the olive pomace (OP) obtained from the production of virgin olive oil. Due to its high amount of phenolic compounds, olive pomace is highly polluting and phytotoxic to the environment, making it one of the most contaminating effluents in the agricultural production system. However, polyphenols can be used in various fields, from the nutraceutical to the pharmaceutical ones, making olive pomace an economical source of various high-value-added compounds. In accordance with the principles of green chemistry, unconventional technologies and the use of GRAS solvents are combined to extract these valuable compounds. Moreover, the CN-Agritech project aims to evaluate and study the operating parameters for the scale up of a high pressure and temperature extractor (HPTE), bringing it from a TRL 4 to a TRL 8. This type of unconventional technology allows the extraction of high value-added compounds using just a mixture of water and ethanol as extracting solvent and by exploiting higher pressures and temperatures.

Polyhydroxyalkanoates Production from Food Wastes as Sustainable Carbon Sources

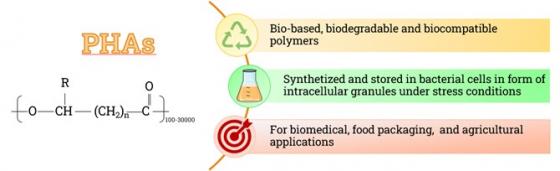

Nowadays, polymers are commonly used for a wide range of applications that play a fundamental role in daily life. The annual worldwide demand of plastics is over 400 million tones and most of the plastics used come from the petrochemical industry. For this reason, the indiscriminate usage and disposal of conventional plastics causes the accumulation of a huge amount of wastes, posing a serious concern about their disposal, environmental and health issues. In order to mitigate these alarming consequences, research is oriented towards eco-friendly bioplastics, like polyhydroxyalkanoates (PHAs). They are bio-based, biodegradable and biocompatible polymers, synthetized and stored in bacterial cells in form of intracellular granules. They find several applications in the food and biomedical sectors. However, their use is still limited by the high production cost. Recently, some efforts have been made to improve PHAs production by using different kinds of organic wastes or industrial by-products as feedstock. Therefore, this research is oriented towards the production of PHAs starting from food wastes, such as spent coffee grounds (SCGs). This permits to reduce the overall cost of the process and it is oriented towards a circular economy view. The goal is focused on extracting and characterizing the carbon source and defining the optimal operating conditions for the PHAs production. Furthermore, the technical feasibility of the process is combined with safety. In fact, starting from a waste stream as feedstock up to the biological production of the polymers, several hazards in the operations and materials should be carefully evaluated. Inherently safer design, if applied to the conceptual design stages, is an approach which allows to minimize the hazards and obtain greater resilience and reliability.

Micro and Nano encapsulation of Bioactive Compounds obtained through the Valorization of Agri-Food Products

Stabilization of the Bioactive compounds

A problem subject of recent research studies concerns the stabilization of the bioactive compounds extracted from the agri-food wastes. In fact, they are very sensitive and easily degradable if exposed to light, oxygen and temperatures. In this context, the research activity focuses on experimental processes for the micro and nanoencapsulation of bioactive compounds in biopolymeric carriers. Various processes have been developed, including spray drying, emulsification, microfluidics, antisolvent precipitation, lipid film hydration, supercritical fluids-assisted methods.

Encapsulation of bioactive substances is a process through which bioactive compounds are trapped within a support material. It is a constantly evolving field of research to find increasingly innovative and high-performance techniques. In particular, the emulsion-based techniques are innovative, versatile and adaptable to several fields. They allow to produce liquid formulations or polymeric particles, that can be able to stabilize bioactive molecules, like polyphenols, antioxidants, natural extracts or drugs, or microorganisms for applications in the food, pharmaceutical, and symbiotic agriculture fields. In this way, it is possible to protect them from external conditions, mask flavor, slow down degradation processes, increase stability and shelf-life. Emulsions are considered as one of the most popular encapsulation and release systems for a wide range of lipophilic, hydrophilic and amphiphilic bioactive molecules, due to their high encapsulation efficiency, maintenance of the encapsulated molecules chemical stability and controlled release. Good results can be obtained both in terms of encapsulation efficiencies and in terms of control of the particle size.

A specific research carried out in this field concerned the stabilization of microorganisms and bacteria with particular beneficial properties for the soil. These microorganisms, appropriately stabilized, can constitute a source of restoring the fertility of the soil. Through the incorporation of these microbial components within a double emulsion of the water-oil-water type it was possible to increase the shelf-life of these natural bio-stimulants up to a maximum of 12 months at room temperature. The results obtained from this research were the basis for the launch of the university spin-off and innovative start-up BEST SRL. This research activity also led to the award in the Liguria Region start up competition in 2019.

Biological Validation of the Bioactive Compounds

The bioactive extracted from food wastes are biologically validated. In particular, the research conducted by the BELONG center involves in vitro assays to assess the anti-inflammatory and antiatherogenic activity of the extracts on endothelial cell lines, for their possible use as dietary supplements. At the same time, the extracts can be used as additives in the formulation of new probiotic products.

The bioavailability of the active compounds can be increased by micro and nano-encapsulation of the obtained extracts.

Production of nanocarriers for Controlled & Target Delivery applications

The objective of this research activity is the production and characterization of nanoparticles encapsulating proteins and engineered on their surface with antibodies to be used in targeted therapy protocols for the treatment of atherosclerosis. The activity presupposes an innovative therapeutic approach for the treatment of atheromatous plaques in the florid phase, avoiding the systemic approach with traditional therapies or with innovative drugs. The studies involved the validation of various nanosystems, such as nanoliposomes, produced by working with both supercritical fluids and polymeric nanoparticles. In particular, interest has focused on the production processes of microparticles, microcapsules and nanoparticles through the use of emulsions. In this process, the polymer and, possibly, the drug are dissolved in the organic solvent of the oil phase of the emulsion. The emulsion production phase is of particular importance, as the emulsion is the primary step for the production of the particles. The research activity, therefore, concerned both the study and optimization of the emulsion production phase and the optimization of the solvent extraction phase, carried out through evaporation and liquid-liquid extraction. The particles produced were then engineered through surface modification techniques in order to obtain a targeted release to target tissues. The results of this research led to the filing of an international patent: PCT/IB2020/057829, “Polymer immuno-nanoparticles for targeted therapy and diagnosis of atherosclerosis”.

The liposome encapsulation technique also gave good results in this particular research context and led to the filing of a second international patent: PCT/IB2020/055404, “Engineered nanoliposomes for targeted atherosclerosis therapy and their preparation process”.

For each type of construct, the production process was optimized by evaluating parameters such as morphology, particle size, encapsulation yield and efficiency, chemical-physical properties, release kinetics of the encapsulated proteins, bio- and hemocompatibility. The ongoing activity aims to evaluate the up-take of nanoparticles by different cell lines, the ex vivo recognition of the engineered nanoparticle towards pathological tissues and the physiological tolerability in vivo on a mouse model.

Food Preservation: Innovative Food Packaging

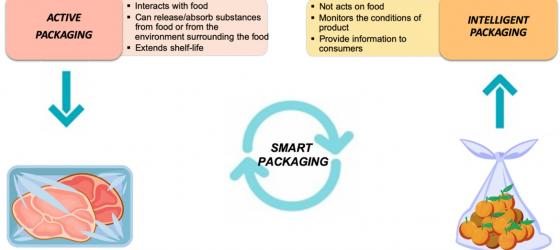

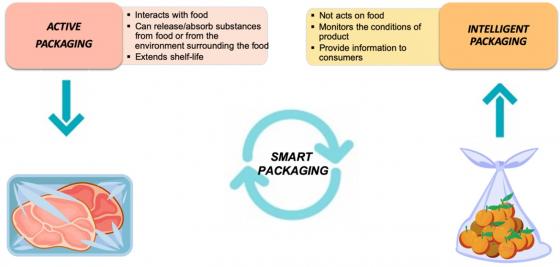

Food packaging has recently become one of the most interesting topics for researchers and companies. In the era of Industry 4.0, the food packaging sector is also abandoning the old concept of simple protection, communication and product containment, to open up to an innovative vision enclosed in two concepts: active and intelligent packaging. These two new packaging concepts can be used to make them work in synergy to produce what is called a smart packaging.

At the same time, the interest in reducing packaging waste volumes has pushed scientific research towards the study of new materials such as biodegradable films, formulated with raw materials deriving from renewable sources, called bio-films.

In these perspectives, the Food Engineering Laboratory has started several projects in the active packaging field. In particular, research studies are dealing with the development of nanostructured antimicrobial bio-films based on compounds of 100% natural origin. As biopolymer matrix, proteins extracted from natural sources such as zein, are selected and optimized. Natural extracts rich in bioactive compounds, obtained using green extraction processes developed in the Food Engineering Laboratory, are instead used for their antimicrobial and antioxidant properties.

Another project regards the production of engineered solutions for smart packaging dedicated to fresh food products. Loss of quality attributes during distribution and storage can occur due to biological, chemical and physical degradation. The innovative aspect of this research regards the phase change materials (PCM) that offer an excellent solution. A PCM is a substance that undergoes a phase transition at a specific temperature, therefore able to absorb and release latent heat when the isothermal conditions are altered. The most commonly PCMs used are: fatty acids, paraffin waxes and hydrated salts. In this field, the research aims to create an eco-compatible polymeric biofilm that has all the main characteristics of a standard food packaging, such as mechanical and barrier properties, and also has the intelligent behavior deriving from the presence of PCMs that allow to maintain the temperature of fresh products constant throughout the entire shelf-life and along the distribution line.

Two different techniques are commonly used for the production of polymeric films: electrospinning and solvent casting. The first one is a simple, versatile and low-cost technology for producing fibers with diameters in the range from nano to microns. In particular, the fibers obtained show a large ratio between surface and volume due to the high porosity and nanostructure, characteristics that allow a prolonged release of the antimicrobial compound from the active packaging film. Solvent casting, instead, allows to obtain a thin, transparent and almost perfectly isotropic film, this technique consists in dissolving polymer in a solvent, depositing the solution in a mold and evaporating the solvent.

Production of Bioresorbable Engineered Biomaterials

This research field, carried on by the BELONG center, was initially developed in collaboration the Massachusetts Institute of Technology, Harvard MIT Health Sciences & Technology, Cambridge, Massachusetts, USA for the production of scaffolds with synthetic and natural, biodegradable and bioresorbable polymers with possible applications in the vascular surgery. The need for such biomaterials, suitable for the replacement of small-diameter occluded vessels or for vascular bypass, is growing due to the increasing incidence of occlusive vascular diseases worldwide, both due to genetic background and lifestyle. To reduce the inflammatory effect, the biomaterials with the best performance are engineered with bioactive compounds, such as antioxidants and proteins. The biomaterials can be subsequently validated in a bioreactor by studying their properties as a function of different working pressures. The data collected during the bioreactor experimentation allowed the development of predictive mathematical models regarding the behavior that the studied vascular prosthesis will have once implanted in a living organism.

Optimization of Industrial Processes and promotion of the technological transfer

In collaboration with industries, such as SIEMENS S.p.A., Domori Illy Group, Coop Italy, Piovan S.p.A., CETENA Fincantieri, Sanitrade S.r.l., studies are constantly performed to optimize the manufacturing lines and promoting the technological transfer of lab-scale plants.