Several instrumentation equipment are available at the Food Engineering Laboratory. In particular, the laboratories are available equipped with several plants and analytical instruments:

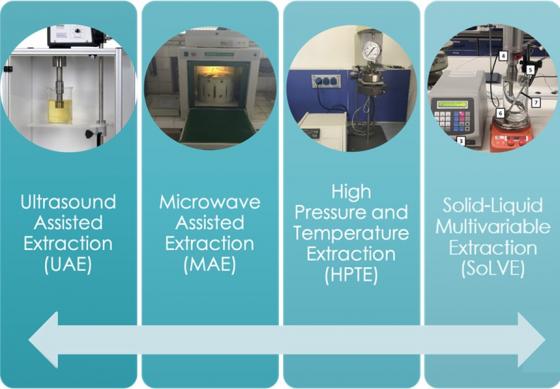

Innovative extraction methods using green solvent are performed through several lab-scale extractions:, Ultrasound-Assisted Extractor (UAE), Microwave-Assisted Extraction (MAE), High Pressure and Temperature Extraction (HPTE), Solid-Liquid Multivariable Extraction (SoLVE).

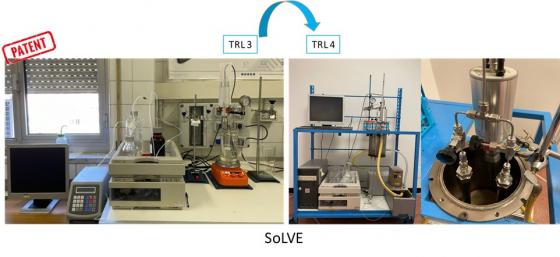

Some of the aforementioned extractors have been also scaling-up to a pilot scale: SoLVE and High Pressure and Temperature Extractor.

In 2019, SoLVE won the Patent for industrial invention: “Process and system for extracting molecules from solid particle matrices”, WO2021090250A1.

Spray dryer: used t

o micronize powder and encapsulate active principles:

Rotor-stator emulsifier: suitable for the homogenization, mixing and emulsification for a wide range of applications.

Microfluidic device: through the use of micrometric channels and different geometries, it allows the manipulation of fluids for the production of droplets or particles, ensuring high control and precision.

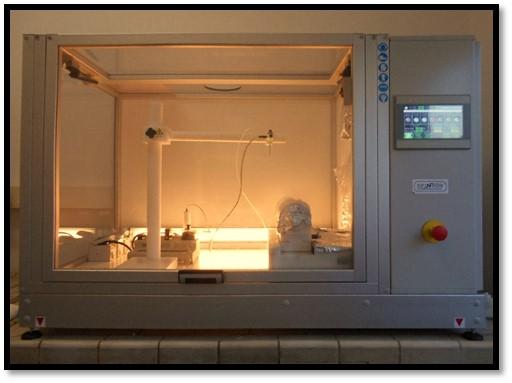

Electrospinning Plant: used to obtain nanometric fibers of different polymers for biomedical and food packaging purposes.

Freeze dryer: operating at low temperatures and very low pressure, it allows the removal for sublimation of a solvent from a solution, previously solidified by freezing.

Analytical instruments are available for product characterizations: spectrophotometer, GC-FID, GC-MS, HPLC, HPLC-MS, FTIR, Mastersizer 3000 Laser Diffraction Particle Size Analyzer.